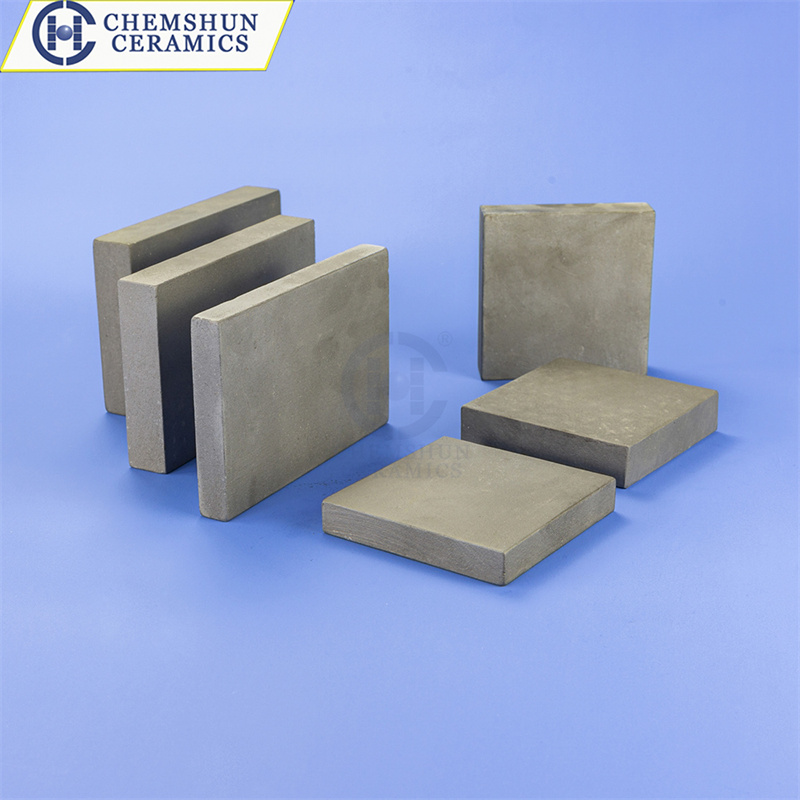

Tile Silicon Carbide na-ejikọta mmeghachi omume

Uru nke Reaction Bonded Silicon Carbide

1) Njupụta dị ala.

2) Nguzogide corrosion.

3) Yiri nguzogide.

4) Nguzogide oxidation.

5) Nguzogide abrasion.

6) Ezigbo nguzogide ujo nke thermal (n'ihi ọnụọgụ mgbasawanye ọkụ dị ala na ihe nrụpụta ọkụ dị elu).

7) Ike dị mma na oke okpomọkụ.

8) Njikwa akụkụ dị mma nke ụdị mgbagwoju anya.

Yiri ngwaahịa na-eguzogide: Silicon carbide plate, silicon carbide brik, Pipe lining, Pipe Cone, cyclone, etc.

Ngwongwo ụlọ: Efere, Beam, Roller, Burner Nozzle, Round doo, square doo, oghere doo.Crucible, Sagger, wdg.

Ndị ọzọ: Desulfurization nozzles

Ngwa nke Silicon Carbide jikọtara mmeghachi omume:

mmeghachi omume silicon carbide egosila na ọ bụ nhọrọ kacha mma maka ngwa eji eyi dị ka ọkpọkọ ọkpọkọ, nozzles, chokes control flow na akwa akwa akwa na Ngwuputa yana ụlọ ọrụ ndị ọzọ.

Isi Parameter

| Njirimara | Nkeji | SiSiC/RBSIC |

| Nnukwu njupụta (SiC) | V01% | ≥85 |

| Nnukwu njupụta | g/cm3 | 3.01 |

| Porosity pụtara | % | 0.1 |

| Modul nke mgbawa na 20 ℃ | Mpa | 250 |

| Modul nke mgbawa na 1200 ℃ | Mpa | 280 |

| Modul nke elasticity na 20 ℃ | Gpa | 330 |

| Mgbaji siri ike | Mpa*m1/2 | 3.3 |

| Thermal Conductivity na 1200 ℃ | wm-1.k-1 | 45 |

| Mgbasawanye thermal na 1200 ℃ | a × 10-6/ ℃ | 4.5 |

| Thermal ujo eguzogide na 1200 ℃ | Ọ dị ezigbo mma | |

| Ọnụọgụ nke okpomọkụ radieshon | <0.9 | |

| Oke.arụ ọrụ okpomọkụ | ℃ | 1350 |

Nha

nwere ike ahaziri dị ka ndị ahịa chọrọ.

Ọrụ

Anyị na-anabata iwu omenala.

Ọ bụrụ na ịchọrọ ịmatakwu ozi ngwaahịa, nabata ịkpọtụrụ anyị na anyị ga-enye gị ngwaahịa kachasị mma na ọrụ kacha mma!