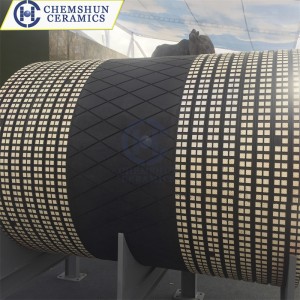

Yiri Ceramic Lined Pulley Lagging na-eguzogide

Njirimara

Magburu onwe corrosion eguzogide ihe onwunwe

A na-edozi nha na ịdị arọ nke dị mfe

Magburu onwe okpomọkụ na-eguzogide ihe onwunwe

Magburu onwe mmetụta na-eguzogide ihe onwunwe

Ngwa ngwa na nrụnye nchekwa

Ọnụ ahịa mmepụta na mmezi dị ala

Uru Ceramic Chemshun

Ndị otu ọkachamara ọkachamara iji nweta atụmatụ CAD

Ndị otu nrụnye ọkachamara iji nweta ọrụ ịwụnye

Usoro akwadoro nke ọma dịka ụkpụrụ mba ụwa si dị

Nabata ọkọlọtọ na taịlị emebere ya

Mpempe akwụkwọ data teknụzụ

| S. Mba. | Àgwà | Nkeji | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Ọdịnaya Alumina | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Njupụta | g/cc | ≥3.60 | ≥3.60 | > 3.65 | ≥4.2 |

| 3 | Agba | - | Ọcha | Ọcha | Ọcha | Ọcha |

| 4 | Mmiri Absorption | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Ike Flexural | Mpa | 270 | 300 | 320 | 680 |

| 6 | Njupụta nke Moh | Ọkwa | 9 | 9 | 9 | 9 |

| 7 | Nkume ọma isi ike | HRA | 80 | 85 | 87 | 90 |

| 8 | Ike ike Vickers (HV5) | kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Ike mgbajiji (Nkeji) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Ike mkpakọ | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Ọnụego Mgbasawanye okpomọkụ (25-1000ºC) | 1 × 10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Okpomọkụ arụ ọrụ kacha | ºC | 1450 | 1450 | 1500 | 1500 |

Akụkụ

| Ngwaahịa | Ogologo (mm) | Obosara (mm) | Ọkpụrụkpụ gụnyere Dimple(mm) |

| Ceramic Tile nwere 5 dimples | 20±0.3 | 20±0.3 | 5/6/7/8/9/10 |

| Ceramic Tile nwere 13 dimples | 20±0.3 | 20±0.3 | 5/6/7/8/9/10 |

| Ceramic Tile nwere 18 dimples | 20±0.3 | 30±0.5 | 5/6/7/8/9/10 |

| Ceramic Tile nwere 13 dimples | 25±0.4 | 25±0.4 | 5/6/7/8/9/10 |

| Hex.Tile | 12 | 3/6/10/11/12/20/24/25 | |

| Hex Tile | 19 | 5-25 | |

| Hex Tile | 6 | 3 ~ 6 | |

| Tile Square | 20 | 20 | 2 ~ 10 |

| Tile Square | 17.5 | 17.5 | 2 ~ 10 |

Ngwa na ụlọ ọrụ

| Ụlọ ọrụ mmepụta ihe | Usoro akụrụngwa | Akụkụ akụrụngwa |

| Simenti | Sistemu ejikọtara ụzọ maka okwute limestone na mmanụ crude | Chute, bonka, pulley lagging, cone na-apụ apụ |

| Sistemụ igwe ihe igwe | Nri nri chute, mgbanaka na-ejigide, efere scraper, mgbanaka akara, pipeline, onye nche ịwụ, cyclone, ntụ ntụ concentrator ahụ, bonka | |

| Sistemụ igwe nri ciment | Chute, bonka, fan vane wheel, fan casing, cyclone, okirikiri duct, ebu | |

| Sistemụ igwe igwe | Ahụ ike pulverizer na wheel vane, ahụ onye na-etinye ntụ ntụ, ọkpọkọ kol gbajiri agbaji, ọwa mmiri na-ekpo ọkụ. | |

| Sistemụ njikwa | Ehulata ụzọ mbata/oghere, efere uru ikuku, cyclone, chute, ọkpọkọ nke na-anakọta uzuzu | |

| Usoro ikpo ọkụ | Ọkpụkpọ ọkpọkọ na mgbidi | |

| Igwe igwe | Usoro nri ihe onwunwe | Hopper, silo |

| Sistemụ batching | Ịgwakọta bonka, agwakọta gbọmgbọm, diski agwakọta, pelletizer diski | |

| Sistemụ njem ihe eji eme ihe | Hopper, silo | |

| Sistemụ mkpochapụ na mkpofu Ash | Pipeline na-emebi emebi, gbagọọ, y-ibe | |

| Sistemụ coking | Coke hopper | |

| Igwe ihe igwe na-agba ọsọ | Cone, buffles nkewa, ọkpọkọ mpụta, ọkpọkọ kol gbasasịrị, cone ọkụ | |

| igwe igwe | Ọkwa, ihe nkesa cyclone, gbagọ, ntụ ntụ ntụ n'ime shei | |

| Ike okpomọkụ | Usoro njikwa coal | Igwe wheel ịwụ, coal hopper, coal feeder, orifice |

| Sistemụ igwe igwe | Ọkpụkpọ nkewa, ikiaka na cone, ikpere igwe igwe na tube kwụ ọtọ | |

| Igwe ihe igwe na-agba ọsọ | coal igwe ihe ahu, nkewa buffles, cone, pipeline, ikiaka | |

| Igwe igwe dara ada | Ọkpụkpọ coal na ikpere aka | |

| Sistemụ mkpochapụ | Pipeline na ikpere aka | |

| Sistemụ mkpochapụ Ash | Shei uzuzu fan, pipeline | |

| Port | Usoro ihe eji eme njem | Diski na ihe mkpuchi igwe wheel ịwụ, ihe nfefe ebe a na-ebufe, ihe ndọba ihe, |

| Na-agbaze | Usoro ihe eji eme njem | Atụ hopper, coke hopper, ihu ihu na-ama jijiji, valvụ isi, eriri etiti, eriri ọdụ |

| Sistemụ batching | ogbe hopper, igwe agwakọta | |

| Usoro ọkụ | Ịwụ ntụ, mgbapụta calcine tube, hopper | |

| Sistemụ mkpochapụ | Pipeline na ikpere aka | |

| Chemical | Usoro ihe eji eme njem | Hopper, silo |

| Sistemụ mkpochapụ | Pipeline na ikpere aka | |

| Ngwa nhazi | Vibromill ihe eji eme ihe | |

| Kọl | Usoro njikwa coal | Igwe wheel ịwụ, coal hopper, coal feeder |

| Usoro ịsa coal | Hydrocyclone | |

| Ngwuputa ihe | Usoro ihe eji eme njem | Hopper, silo |

Ọrụ

Anyị na-anabata iwu omenala.

Ọ bụrụ na ịchọrọ ịmatakwu ozi ngwaahịa, biko nweere onwe gị ịkpọtụrụ anyị ma anyị ga-enye gị ngwaahịa kachasị mma na ọrụ kacha mma!

Mkpado ngwaahịa

Dee ozi gị ebe a ziga anyị ya